The charm of aluminium foil containers and ZONGBOU's one-stop solution revealed

In today's packaging market, aluminium foil containers are the preferred choice of many customers because of their unique advantages in a wide range of applications. Whether Wrinkle Wall Aluminium Containers or Smooth Wall Aluminium Containers, they play an important role in different scenarios with their own characteristics. Behind this, ZONGBOU offers a one-stop solution for aluminium foil container production equipment, from the foil product to the foil production machine.

Attractiveness of Wrinkle Wall Aluminium Containers

Wrinkle Wall Aluminium Containers stand out in the market with its unique design. Its wrinkled walls not only add a visually unique texture, but also provide better handhold stability. In practice, these containers are particularly good at retaining heat, effectively keeping food at the right temperature for a longer period of time, whether it is hot or cold. For the catering industry, this means that the quality of the dishes can be better maintained and the customer's dining experience can be enhanced. For food processing companies, its diverse applicability can be used in the packaging of a wide range of products, such as baked goods and convenience foods, adding a distinctive feature to the marketing of products.

Advantages of Smooth Wall Aluminium Containers

Smoothwall Aluminium Containers attract many customers with its simple and beautiful appearance. Its smooth surface gives people a delicate, high-end feeling, especially suitable for high-end food or gift packaging, can significantly enhance the grade of the product. At the same time, the easy-to-clean feature makes it favoured in frequent-use scenarios such as catering, greatly reducing cleaning costs and time. Moreover, good printing adaptability provides a wide space for brand promotion, and enterprises can display brand image and product information on containers through exquisite printing to enhance the market competitiveness of their products.

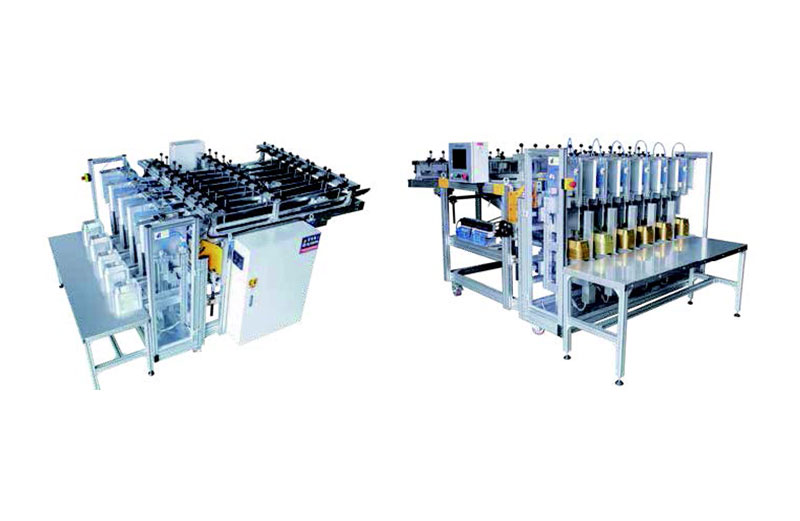

ZONGBOU's one-stop solution I. Machines and equipment

ZONGBOU understands the various needs and concerns of customers in the production process of aluminium foil containers, so it provides a comprehensive one-stop solution. It not only covers high-quality aluminium foil products, but also includes two types of aluminium containers, Wrinkle Wall and Smooth Wall, to meet the diversified needs of different customers.

1. Aluminium Foil Container Machine

* Advanced Manufacturing Process

ZONGBOU's Aluminium Foil Container Machine adopts advanced manufacturing technology to accurately process aluminium foil into containers of various shapes and sizes. Both Wrinkle Wall Aluminium Containers and Smooth Wall Aluminium Containers can be efficiently produced on this machine. The high machining accuracy ensures consistent dimensions for each container, facilitating subsequent packaging and use.

The machine's high level of automation reduces the number of manual operations, which not only improves production efficiency but also reduces production costs. At the same time, automated production can also better ensure the stability of product quality and reduce quality fluctuations caused by human factors.

* Versatile design

The machine can be flexibly adjusted according to the different needs of customers and is capable of producing aluminium foil containers of different capacities and shapes. Whether the containers are round, square or other special shapes, they can be easily realised. This versatility meets the diversified packaging needs in the market and enables customers to produce a wide range of products on the same machine, expanding their business scope.

The Aluminium Foil Container Machine also adapts well to aluminium foil materials of different thicknesses. It can automatically adjust the processing parameters according to the characteristics of aluminium foil to ensure that high-quality containers can be produced under different materials, providing customers with more space for material selection.

2. Supporting Equipment

- Unwinding System

Efficient unwinding system is one of the most important parts of aluminium foil container production, ZONGBOU's unwinding system is able to unroll the aluminium foil coils stably and provide continuous supply of raw material for the subsequent processing. It features precise tension control to avoid slack or over-tightening of the aluminium foil during unwinding, ensuring flatness and stability of the aluminium foil.

Equipped with advanced sensors and control systems, the system is able to monitor the parameters during the unwinding process in real time and make automatic adjustments. This reduces production interruptions and material wastage due to unwinding problems and improves production efficiency and material utilisation.

- Wastage packaging system

During the production of aluminium foil containers, a certain amount of waste is generated, and ZONGBOU's Wastage Packaging System is able to collect and package this waste in a timely and efficient manner. It uses an automated collection device to concentrate the scrap and neatly packs it through compression and packaging equipment for subsequent processing and recycling.

The use of the waste packaging system not only helps to keep the production site tidy, but also reduces the impact of waste materials on the environment. At the same time, through the rational recycling and disposal of waste materials, it can also save a certain amount of cost for customers and improve the utilisation of resources.

- Aluminium Foil Container Stacker

Aluminium Foil Container Stacker is responsible for neatly stacking the produced containers for transportation and storage.ZONGBOU's stacker is highly automated and intelligent, and can quickly and accurately stack containers in a predetermined way. It automatically adjusts to the size and shape of the containers to ensure stability and neatness.

The stacker is also equipped with safety protection devices to avoid damage to containers during the stacking process. At the same time, it can be seamlessly integrated with other production equipment to improve the automation and productivity of the entire production process.

Field of application (application areas)

* Food packaging industry

Aluminium foil containers are widely used in the food packaging field because of its good freshness, heat insulation and safety.ZONGBOU's products can be used to package various kinds of food, such as fast food, bakery food, convenience food, frozen food and so on. Whether in supermarkets, restaurants or takeaway markets, aluminium foil containers made by ZONGBOU can be found. They provide a reliable packaging guarantee for food, extend the shelf life of food, and also enhance the appearance of food.

* Airline catering service

In the aviation sector, where the requirements for food packaging are very strict, ZONGBOU's aluminium foil containers are the ideal choice for airline catering, thanks to their lightness, good sealing properties and ease of processing. They can be used to package meals on board aircraft, ensuring the quality and safety of food in high-altitude environments. Meanwhile, the exterior design of the foil containers can also be customised to suit the airline's brand image, providing passengers with a better dining experience.

* Gift Packaging Market

As people's standard of living improves, the demand for high quality and personalised packaging in the gift packaging market continues to grow. zongbou's smooth-walled aluminium foil containers are ideally suited for gift packaging due to their delicate appearance and good printing adaptability. For example, chocolate gift boxes, tea gift boxes, cosmetic gift boxes, etc. The use of aluminium foil containers for packaging not only enhances the grade of the gift, but also serves to protect the product. Through exquisite printing and design on the container, the unique charm of the gift can be shown to the fullest, to meet the high demand of consumers for gift packaging.

* Other fields

In addition to the main application areas mentioned above, ZONGBOU's aluminium foil containers and related equipment are also used in medical and chemical fields. For example, in the medical field, aluminium foil containers can be used to package some medicines and medical devices because of their good moisture-proof and oxidation-proof properties; in the chemical field, they can be used to package some chemical reagents and other products to ensure the quality and safety of the products.

In conclusion

ZONGBOU, as a professional supplier of aluminium foil container production equipment, provides quality solutions to customers in many fields by offering advanced machines and equipment, customized moulds and full range of services. Whether for companies pursuing high-quality products or for customers with individual requirements, ZONGBOU can meet their needs and help them succeed in the market.